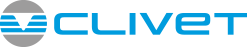

Heat pumps have become increasingly popular over the last few years as a heating and cooling system, but many are unaware that these systems rely on refrigerants to operate. In this article we explain how refrigerants work in heat pumps and what their environmental impacts are.

Thanks to their energy-saving and efficiency features, heat pumps are not only an innovative system for heating, cooling and producing domestic hot water, they are also a key element in the European Union’s strategy to combat climate change. Yes, because, as everyone knows, the primary goal of the European Green Deal is for all EU countries to achieve climate neutrality by 2050.

Decarbonisation

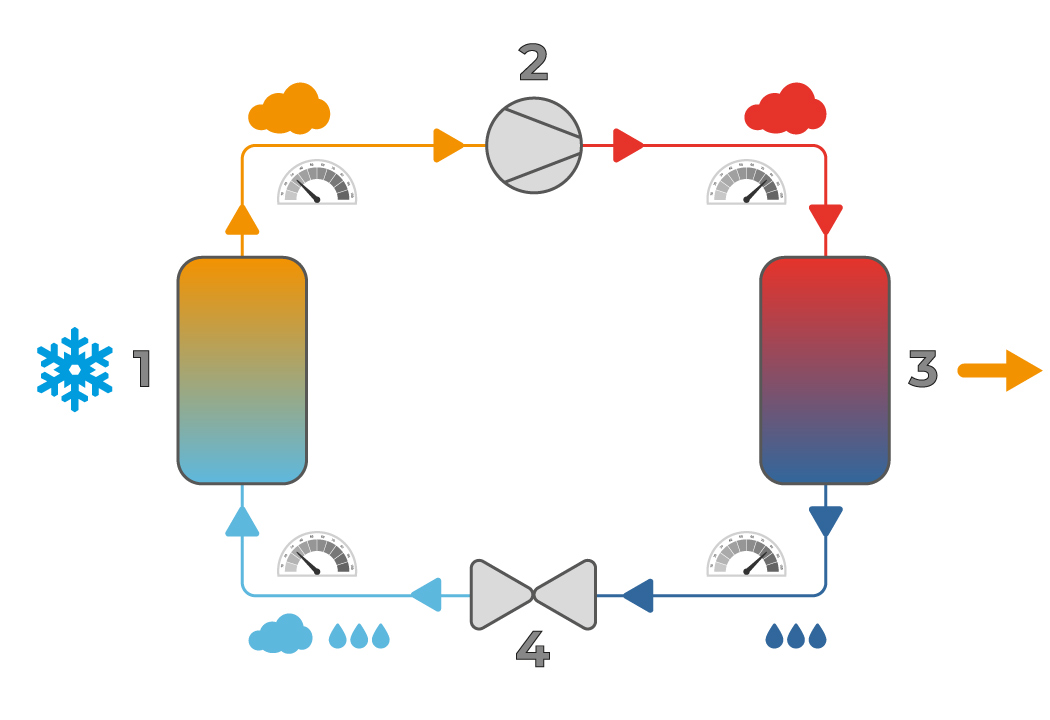

Europe is regulating the use of refrigerants with the primary goal of achieving decarbonisation in the near future. Decarbonisation, which is an essential ally in heat pumps, is a milestone since the extraction of energy from the ground, air or groundwater needed for their operation results in a total absence of fuel gas use.

The energy efficiency of heat pumps

As energy-related products, heat pumps fall within the scope of application of the European Parliament Directive no. 2009/125/EC of 21 October 2009, which regulates their eco-design and the definition of minimal eco-design specifications. A Directive that has given rise to numerous implementing regulations over the years, such as Regulation 813/2013 for single and combined heating systems, and that in 2021 alone saved more than 120 billion euros in energy. On the other hand, Directive 2010/30/EU of 19 May 2010 introduced energy labelling for energy-related products, including heat pumps, which indicates their consumption by means of an energy rating and certain other parameters.

The use of renewable energy

When talking about renewable energy, it is impossible not to refer to the so-called Renewable Energy Directive (2009/28/EC), a Directive focused on the development and distribution of clean energy in all sectors of the European economy, which has steadily expanded its targets over the years. After achieving the first target of producing at least 20% renewable energy by 2020, with consumption rising from 12.5% in 2010 to 21.8% in 2021, the European Commission has proposed to reach 40% by 2030. With RePowerEU, the plan launched in May 2022 in response to the emergence of energy market issues due to Russia’s invasion of Ukraine, the idea is to raise this percentage to 45%.

Moreover, with this initiative, EU countries have reduced their dependence on Russian fuels, saved about 20% energy and introduced a cap on gas and oil prices.

United Arab Emirates

United Arab Emirates  +971 (0) 4501 5840

+971 (0) 4501 5840  info@clivet.ae

info@clivet.ae  France

France  Germany

Germany  +49 40 325957-190

+49 40 325957-190  United Kingdom

United Kingdom  India

India  Russia

Russia  South East Europe

South East Europe